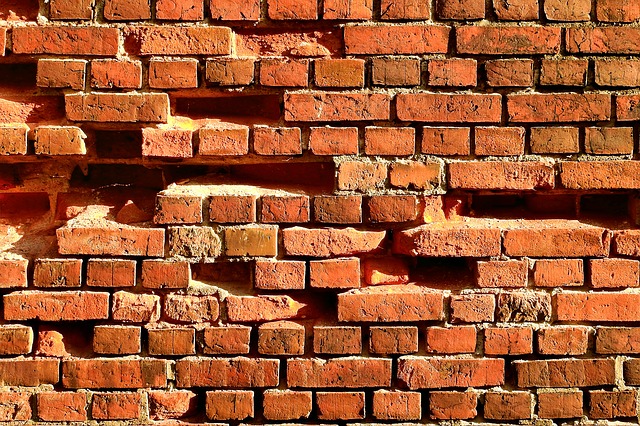

Not all masonry repair projects are the same. It depends on the type of structure being repaired, the needs of the client, and what the professional thinks would be the most effective. The materials used in a masonry project also depend on availability and cost. Since each masonry job is different, they each require different materials. Here are a few of the common materials used in masonry repair.

(more…)