Mortar is a very important material in masonry construction because it’s what holds everything together!

When it comes to masonry, mortar may be the most essential part of the construction. Mortar is what is used to bond the materials of your masonry together, providing the structural integrity of the project. Depending on the type of project you are working on, different types of mortar can be used. Each class is best matched with a different kind of construction due to the differences in performance. Depending on your application you may want to use one over another, which is why knowing the differences is so important. There are four primary mortar types M, O, N, and S; today we’ll take you through what each is and where it is best used.

M

With the highest starting psi, type M mortar also uses the largest levels of Portland cement. Type M is most often used for driveways, foundations, retaining walls, and natural stone. Despite its extreme strength, it has poor sealing and adhesion properties which make it ill-suited for most applications where it would be exposed.

O

With only around 350 psi, type O mortar has the lowest compression strength of modern mortar, but it still is incredibly useful. Its primary function is for use in above-grade, non-load-bearing walls, and interiors. It’s particularly valuable for repair and repointing work on other structures thanks to its easy application and consistency.

N

If you’re working on above-grade walls and exteriors that will be exposed to high temperatures and severe weather, this type of mortar is highly recommended. It is considered to be an all-purpose mix that offers medium compression strength and great general application. It is regarded as the most commonly used mortar for home-owners and has a 750 pound per square-inch strength after 28 days. Type N is made from a mix of lime, Portland cement, and sand. It’s the preferred type for soft stone masonry and is useful for interior load bearing, exterior, and above grade installations.

S

With a high strength level, weighing in at 1,800 psi and a high-tensile bond, S mortar is a perfect fit for a variety of projects including those at or below grade. It is often used for retaining walls, sewers, manholes, and masonry foundations in below grade projects. It is also an excellent choice for masonry structures like walkways and brick patios. Although it already is able to withstand seismic loads, wind and soil pressure, it can be mixed to achieve an even higher psi level.

Contact Del Prete Masonry Today for Your Next Construction Project!

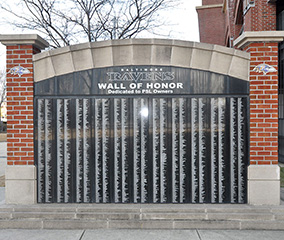

If you are ready to upgrade your home or commercial building with professional masonry installation or replacement, Del Prete Masonry has the experience and expertise to get the job done right for the right price. To explore our residential and commercial services and set up a consultation, please give us a call at 410-683-0650 or contact us online. We currently serve Baltimore City and County, Harford County, Carroll County, Anne Arundel County, and Howard County. To see examples of our work and get more updates, follow us on Facebook, Twitter, Google+, and Pinterest.